|

Flipping the craft over wasn't all that difficult. This yahoo on the right

is my buddy James, who helped me with The Flipping. He is currently one

of my few dependable friends, and came over with only a couple of hour's

notice to give me a hand.

Getting it up on it's side was quite easy, once we dislodged it from the floor. When I did my first seam, I didn't seal the cracks before filling with microballoon putty. As a result, the putty slowly drained out of the seam, bonding the craft to the floor. By the time I realized what was going on, it was too late. Fortunately, the only damage done is that of time: I'll have to sand the excess putty off the bottom of the craft and the floor of my carport. No biggie. Hull weight at this point is estimated to be between 100 and 125lbs. |

|

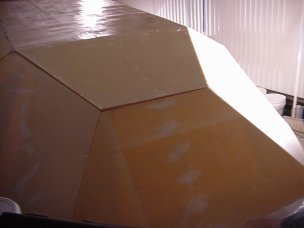

This picture came out looking really neat:

Inside the fan bay. The little white thing in the second picture is my hatch.

Upside down...

Bow & rear side panel. You can see the hole in the side panel that will, with any luck, eventually duct air into the skirt.

Underneath the craft. The boxes originally contained pails of fiberglass resin. Now they're taped together, supporting the bow of the craft so the helm doesn't break under the weight. With any luck, they'll continue to hold it for a couple of days until I finish my seams. Otherwise, I'll have to re-do the helm - which is a time consuming job, making sure the correct angle is held across the entire helm.